Safe Use, Transparency and Information

Safe Use, Transparency and Information

Quality, performance and safety are of highest priority.

Societal benefits with high-quality products

Clariant does not want to create solely functional or solely high-quality products with its developments. Alongside quality and performance, Clariant wants to offer especially beneficial products, products that offer customers and especially consumers an above-average added value. Areas in which the Clariant products provide specific social benefits include medical and pharmaceutical packaging, mosquito nets with long-term effects, flame retardants or solutions for the food industry, which contribute to improving the quality and lifespan of food.

Protection against malaria infections

The World Health Organization (WHO) estimates that around 3.2 billion people, half of the world’s population, are at risk of contracting malaria. Malaria is a widespread and often deadly disease triggered by mosquito-transferred single-celled parasites. It is most commonly found in developing countries. Around half a million people still die each year from the disease, but fortunately the number of new malaria infections and related deaths were reduced by 37% and 60%, respectively, between 2000 and 2015.

An important tool in the fight against malaria is mosquito nets. The WHO recommends nets treated with insecticides that kill mosquitoes on contact, known as insecticide-treated mosquito nets (ITNs). An even more effective type of net are those that last for several years: Long-lasting insecticidal nets (LLINs).

There are fewer than a dozen manufacturers worldwide that offer quality nets certified by the WHO. Clariant has developed a masterbatch technology for LLINs which is regarded as one of the best on the market with respect to bio-efficiency. One criterion used by the WHO is that the nets can be washed at least 20 times without losing their effectiveness, and Clariant’s technology enables the nets to meet this requirement.

The masterbatches produced by Clariant are innovative because, in addition to its mechanical protective function, there is an insecticide incorporated into its fibers that kills mosquitoes on contact but is harmless to people. The fiber net has a storage function for the insecticide, making the nets effective for a guarantee of five years.

Through this innovative technology, Clariant is contributing to the global fight against malaria.

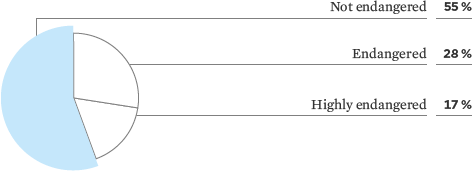

PROPORTION OF THE MALARIA-ENDANGERED PEOPLE IN THE WORLD POPULATION (2012)

Sources: World Health Organization, United Nations

Mold protection

Food spoilage during transportation over long distances is a serious problem. The United Nations Industrial Development Organization (UNIDO) estimates that up to 40% of the food harvested worldwide each year is lost in transit. Containers used for transport of food and other goods are prone to condensation (so-called container rain) that promotes growth of mold and mildew, odor, changes in taste and texture. Cartons and packing materials are also affected by water, which may impair the sturdiness of the packaging and lead to cargo damage. The safe transportation of food is therefore a critical factor in the fight against global food loss.

To protect against moisture and spoilage during transport, Clariant has developed Container Dri® II, which offers reliable protection against moisture and water damage. The formation of condensation is effectively prevented. Rice or cereals no longer become rotten or moldy. Container Dri® II absorbs up to three times its own weight in water and stores it in a special gel that will not harm the health of consumers or the environment. With a significantly less humid environment, food can be kept for much longer while also decreasing costs and waste.

Container Dri® II from Clariant is completely non-toxic and the saturated dehumidification bags can be disposed of as normal industrial waste. The product offers a high level of safety and is extremely effective for all temperature and humidity ranges. Container Dri® II is already used in the shipping of American food aid for developing countries and dramatically reduces the amount of spoiled grain at the destination.

Healthcare and pharmaceutical packaging

Clariant Masterbatches provides numerous products for the medical and pharmaceutical field: from packaging to medical devices to laxatives. No standard products are delivered, but innovative and efficient solutions. In this manner, Clariant produces packaging that protects medicines and medical devices from any impact due to moisture or oxygen and are therefore essential for the purity and durability of the products. These materials are either directly integrated into the packaging material or added as an additional component such as in the closure stoppers of tablet tubes or in the form of separately enclosed capsules. Clariant is a world leader in this kind of active protective packaging for the pharmaceutical industry with around 32% market share. Customer trust in the high quality of products plays a crucial role in the pharmaceutical industry.

The polymer product MEVOPUR® (see Efficiency at Product Level) is excellently adapted for both medical devices such as drug delivery pens, diagnostics, such as blood collection tubes, and bottles and closures used for packaging of pharmaceutical products. A special feature is the ability to supply MEVOPUR® in a variety of colors without undermining the product quality, regulatory requirements and functionality. Color is widely used in the Healthcare sector for identification of the device or drug type that helps protect against mix-ups, and thereby facilitates the work of medical staff and increases patient safety, Clariant has extensive knowledge of modification of polymers for functionality in medical devices and pharmaceutical packaging. This knowledge applied to the MEVOPUR® range offers possibilities to improve sustainability through the reduction of use of materials, reduce friction to improve ease of use of drug delivery devices, protect the polymer during sterilization, and reduce the use of solvent-based inks through laser marking.

These are plastic additives in the form of granules with dyestuffs or other additives used to dye or alter the properties of natural plastic. VIEW ENTIRE GLOSSARY