Invoque™

ECOTAIN® APPROVED

Invoque™ fulfills the criteria of EcoTain®, our approach to sustainability on product level.

Discover Value – Invoque™

»The Clariant Invoque™ system enables problem owners to boost the process of dewatering sediments, to improve the quality of filtered water and to optimize the energy consumption in liquids-solids separation processes.«

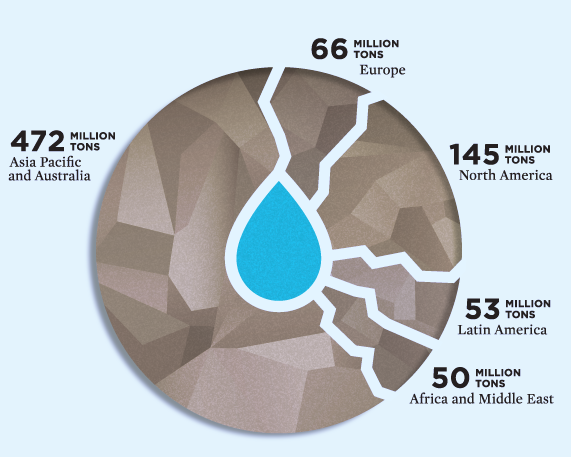

Year after year, around 800 million tons of water-borne sediments – accumulations from shipping channels, port basins, mining activities etc. – are processed worldwide. Of this, approximately 30% may be polluted with toxins (fertilizers, pesticides and other chemical pollutants and heavy metals). Such sediments may not be used, but nevertheless require costly dewatering, with the associated risk that some contaminants will be released in the filtrate water. Retaining contaminants within the sediment and producing a drier transportable material, while generating a cleaner filtrate can dramatically reduce water treatment and sediment disposal and storage costs. Some temporary storage structures, such as mine tailings dams represent a substantial risk, a fact that was demonstrated in an environmental disaster in the fall of 2015 in Brazil, where a large iron ore tailings dam failed. This released over 60 million m3 of contaminated water, containing arsenic, aluminum, lead, copper and mercury, among other elements into the Rio Doce and is one of the worst environmental disasters in Brazil’s history.

Dewatering can be an expensive activity, especially where required for contaminated and/or difficult-to-dewater sediments. Systems may range from spoil-fields and/or lagoons, to expensive processing plants with associated separation, thickening, pressing and storage areas. Many such sediments require chemical coagulation and flocculation prior to or post thickening, to promote effective filter cake formation for the dewatering process. However conventional conditioners can increase the environmental burden in the supernatant water and/or residual solids, leading to increased water and energy requirements as well as other downstream costs and complexity. The total cost of treating and disposing of such sediments can be in the hundreds of euros per ton in some cases.

Invoque™

94%sediment solids achieved in just 24 hours

As an alternative, Clariant has developed an innovative method by which dewatering performance, sediment dryness and water quality are substantially improved: Invoque™. Invoque™ uses patented mineral technologies that are safe for the environment and that facilitate enhanced dewatering performance while simultaneously binding trace contaminants within the filter cake. Each Invoque™ solution is specifically tailored for the individual sediment requirements, to achieve the maximum balance of dewatering and contaminant management. Invoque™ uses high specific surface area mineral conditioners that combine to destabilize and flocculate sediments and adsorb contaminants.

Invoque™ is added to the dredged silt and sludge where it »captures« the finest pollutants and particles, causing them to agglomerate into small flocs that hold less water than conventional floc structures and are easier to dewater, forming a dense matrix. The conditioners employed in Invoque™ are benign to the environment and so cause no additional environmental burden beyond what is already included within the sediment. The Clariant technique is highly efficient and simultaneously very affordable, with lower operating cost and increased opportunities for reuse of water and sediment – and, with a more intense dewatering of the sediment and a more powerful filtering out of contaminants, it provides better results than other solutions. In certain cases, Invoque™ has achieved sediment solids of up to 94% in just 24 hours, producing an absolutely clear filtrate that is approved for immediate return to the environment.

Less water in the sediment leads to lower weight by volume and the more dense material also results in lower absolute volume. This results in lower space requirements for storage, and fewer vehicle movements (lower logistics costs). Furthermore, the use of minerals generally improves the mechanical properties of the sediments, making them more readily available for second use applications.

The use of Invoque™ for dewatering mine tailings in copper ore mining, for example, led to such good results that the customer was able to substantially offset environmental water discharge concerns and make the recovered material available for re-mining. For the dewatering of coal sludge, Invoque™ also yielded a sediment with a high dryness and high calorific value, which could be recovered for steam generation. Using Invoque™ technology, a large port operator was able to fully offset disposal costs of around EUR 100 per m3 associated with approximately 20 000 tons of sediment, by improving sediment dryness and stability, enabling it to be recovered and reused as a concrete additive in the construction of the container terminal, leading to savings in material costs.

Invoque™ fulfills the criteria of EcoTain®, our approach to sustainability on product level.

Discover Value – Invoque™