Ms. Fuenfstueck, are there unique aspects of digitization in the chemical industry compared to other sectors? And how do you see the digitization landscape in the chemical industry changing right now?

Britta Fuenfstueck Compared with industries such as media, retail and telecommunications, the chemical industry is lagging behind. While some digital processes, such as control systems for plant operations, have been ingrained in the chemical industry for a while, the industry has only embraced the new digital wave more broadly over the last few years. The key focus lies in operations, from advanced operations management to predictive maintenance.

Are cost savings or increased service quality – or both – the main benefits of digitization?

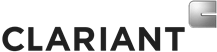

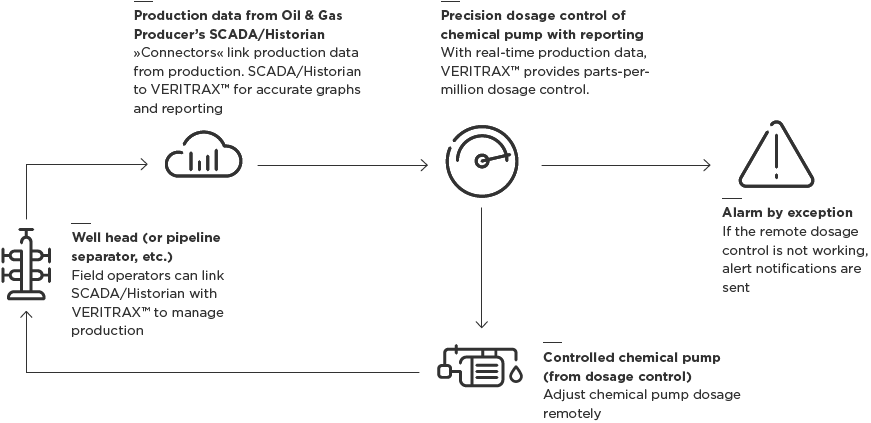

In the chemical industry, the primary focus has been cost savings, although some companies are also looking into digital marketplaces. The service aspect of digital is less developed. However, at Clariant our focus will be in the opposite direction: We want to emphasize identifying new, differentiating offerings for customers. Of course, adding digital tools to our operational excellence approach is important as well.

Does successful digitization mean automating existing processes, or reinventing the entire business model?

Ideally, digital approaches make it possible to do things differently. Imagine the classic example of preventive maintenance. Instead of waiting for a part to deteriorate or conducting checks at standard intervals, digital tools can monitor processes constantly and trigger a maintenance activity at the right time to keep operations intact. On the customer-facing side of business models, the breadth of opportunities that digitization creates is even bigger, but realizing them is also harder.

Are radical digitization overhauls driven more by increasing customer expectations or by solution providers such as Clariant?

At the moment, only our customers in the area of oil production are starting to demand digital offerings, sometimes even in tenders. But innovation is not only about following a well-articulated need; it is about understanding the customer need more deeply, and addressing it proactively. The goal is to build a sustainable digital solution that meets real market issues instead of building offerings with hopes there is customer interest.

How do you expect the area of digitization to develop in the future?

Fastforwarding to 2030, we expect much broader adoption of digitization in personal and business processes. This will likely affect all areas of business, with the focus on turning the current digitization trend into tangible returns.