Natural clay for Paris Metro

Contribution to SDGs

This story is an example of Clariant’s contribution to SDG 9 and SDG 12. Read more in Sustainable Development Goals

-

Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation

-

Ensure sustainable consumption and production patterns

By 2030, the Grand Paris Express will bring sustainable mobility and a new quality of life to the French metropolis. Clariant is doing its part to make it a reality.

It has been called a parallel city underground and »as deeply embedded in the French psyche as it is in the limestone and gypsum of Paris itself«: the Paris Metro. With its Art Nouveau entrances, this 120-year-old subway system is a postcard icon of the French capital. But unlike other icons, say the Eiffel Tower or the Arc de Triomphe, this one is extremely useful to the roughly two million residents of Paris. And come 2030, it will serve even more people, as it turns into one of the largest and arguably most modern metro networks in Europe. The Paris Metro gets a long-overdue update – with a little help from Clariant and a natural clay that is mined not far from the city.

With its 245 stations within the historic center, the Paris Metro is one of the densest metro systems in the world today. But its layout has not kept up with the growth and sprawl of more than a century. Not even one in five of the metropolitan region’s residents lives in the city’s core itself – a lower ratio than in most of Europe’s large capitals. The historic cores of Berlin, Rome, and Madrid all house more than half of their respective metropolitan populations. In London, it is close to a quarter. La Défense, one of the largest business districts of Paris, and indeed Europe, lies outside the well-connected center, as do some of the city’s universities and most of the region’s public housing.

France

The largest transport project in Europe

With an eye on the Olympic Games in 2024, France has launched a massive infrastructure project, known as the Grand Paris Express. This ambitious project aims to double the size of the existing metro system by adding 68 new stations and 200 km of new track. Unlike the existing metro, which generally runs radially from the centre of Paris, the new lines will mostly form a loop around the city.Source: Société du Grand Paris (www.societedugrandparis.fr/gpe/carte)

LEFT Jérémy Prud’Homme

Technical Service Manager, Business Unit Functional Minerals

MIDDLE Laurent Nicolas

Head of Business Group Civil Engineering Europe, Business Unit Functional Minerals

RIGHT Jocelyn Ranc

Civil Engineering Product Manager, Business Unit Functional Minerals

Connecting millions more

To remedy this, Paris is expanding its metro system with what it calls the »Grand Paris Express« – a new automated transit network for the entire capital region. It will add four new lines, a total of 68 interconnected stations, and about 200 kilometers of additional tracks – 90% of which will run underground. Grand Paris Express will add a ring route around Paris as well as new lines and line extensions going outward to connect a host of developing neighborhoods, business districts, and research clusters as well as three of the city’s airports. This will in some cases cut travel times to less than a third, hopefully relieving congestion and reducing motor traffic overall. According to some estimates, Grand Paris Express will help save up to 27.6 million tons of CO2 emissions by 2050. Once completed, the fully automated system will transport two million additional commuters per day, with some lines running every 85 seconds. It’s no wonder why Grand Paris Express has been called »the most ambitious new subway project in the Western world.« And as if that weren’t enough, France’s regional commuter system Réseau Express Régional (RER) is simultaneously tunneling its own new express link, called Est Ouest Liaison Express, or EOLE, right through the heart of Paris.

»There is a lot of digging going on,« says Laurent Nicolas, Head of the Civil Engineering group for Clariant’s Business Unit Functional Minerals. »Grand Paris Express alone will involve removing a volume of soil equivalent to eight times that of the Great Pyramid of Giza.« And it’s not just digging the tunnels, which run at an average depth of around 30 meters. Boreholes for safety access and ventilation shafts go down to around 80 meters, as do the excavations for some of the almost stadium-sized stations.

Clariant’s Business Unit Functional Minerals and the team around Laurent Nicolas play a supporting role in these excavations – quite literally. When building any of the underground structures, construction companies first establish so-called diaphragm walls. That involves drilling deep rectangular trenches with the help of drilling fluids around the area that needs to be excavated. These trenches are then filled with reinforced concrete, essentially creating a submerged concrete box, which can then be emptied out to house anything from a stairwell to an entire multi-level metro station.

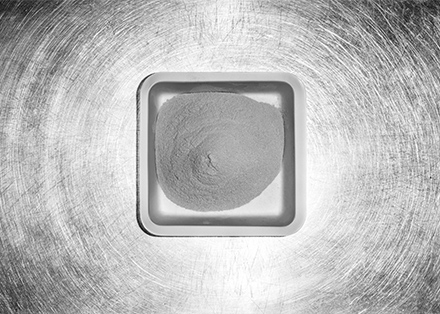

It’s for drilling these trenches that Clariant delivers an essential ingredient: bentonite. The naturally occurring clay forms over eons when volcanic ash is trapped underground and chemically altered under immense heat and pressure. Clariant’s Business Unit Functional Minerals is one of the world’s leading bentonite providers. Every year the company mines close to two million tons of raw clay at its 25 sites in 14 countries all over the world. Clariant is especially committed to sustainable mining practices and takes great care when renaturalizing its bentonite mines, sometimes even achieving higher levels of biodiversity than before exploitation. Bentonite can be tailored for use in a whole range of industries and applications – from metal casting to paper production, and from packaging desiccant to edible oil refining. It even helps with purifying drinking water.

Tight spaces

Large excavations, like the one at this construction site in Paris, rely on copious amounts of drilling slurry to stabilize trenches.

Acting as solid or liquid

In construction and other drilling applications, such as oil and gas production, bentonite is widely used to form drilling fluids, also known as drilling muds. When mixed with water, the bentonite powder swells and forms a slurry with extraordinary properties: Left still and unstirred, the slurry acts almost like a solid or a thick gel. But once it’s moved with enough energy, it turns fluid again and is as easy to pump as chocolate milk through a straw. The technical term for this kind of behavior is thixotropy, and it is immensely useful. »There are basically two main things the drilling slurry does,« Nicolas explains. »It stabilizes the excavation and, depending on the digging technique, ensures an efficient removal of the excavated material, for example, by pumping it.«

To prevent their trenches from collapsing before they can be filled with concrete, the construction company keeps the borehole flooded with drilling slurry. »Otherwise, once you hit groundwater or loose ground conditions, the soil surrounding your borehole becomes so unstable that it would just collapse to fill the void,« Nicolas explains. Once the excavation has reached its targeted depth and the rebar cages are installed, the slurry is then replaced by simply filling the hole with concrete from the ground up.

However, getting the slurry just right for each and every borehole is a science in itself. »It all depends on the ground conditions,« says Nicolas. In order to avoid having to turn to polymer modifications, Clariant has mastered the art of gently coaxing ever more performance out of the natural and eco-friendly clay to fit almost any ground. »The deeper you go, the more complicated the geology can get, at least here in central Europe. And you can never be a 100% certain what to expect.« Especially gypsum, which is particularly prevalent underneath Paris, can be tricky. »It can react chemically with the bentonite and degrade the properties of the slurry if you don’t know what you’re doing,« says Nicolas. That in turn can result in leakages and imperfections in the diaphragm walls, which spells trouble further on in the construction process.

Luckily, Nicolas and his team know how to handle almost any ground condition and adapt the use of bentonite to get the best results. A self-described »old warhorse,« Nicolas has been with Clariant for two and a half decades and has worked on some of the largest construction sites in the world. Nicolas also regularly gives workshops and helps write guidelines for industry bodies, such as the European Federation of Foundation Contractors (EFFC), on drilling techniques, support fluids, and the use of bentonite.

Still, Grand Paris Express is a one-of-a-kind project even to Nicolas. And not just because it’s so vital to his home capital. »The scale of the project, the depth involved, the geology, the tight spaces in a metropolis, or the strict regulations – those are nothing new to us in and of themselves,« he says. »But with Grand Paris Express you have all these challenges coming together, which makes work on any of the more than 200 lots very complex.« And then there’s the time frame. While the entire project is set to be completed in 2030, large sections of the new metro system will actually have to be running by 2024, when Paris hosts the Summer Olympics. »That is a challenge to everyone involved,« says Nicolas. However, helping drilling contractors deal with almost any challenge that mother nature or their customers might throw at them, is what Nicolas and his team do all the time.

Jérémy Prud’Homme is part of that team as a Technical Service Manager. »He is my eyes and ears on-site,« as Nicolas puts it. Prud’Homme checks in on several lots for Grand Paris Express almost every day. Like Nicolas, Prud’Homme has a background in material science and has worked as an engineer in the oil and gas industry. He is exactly half Nicolas’ age. »Most of the civil engineers I talk to on the contractor’s site are of my generation,« Prud’Homme says. »That helps to build a rapport.« However, unlike his contemporaries at construction or drilling companies, Prud’Homme doesn’t spend months or even years working on just one site. He sees about a hundred project sites a year. This wealth of experience often helps him to identify problems and come up with a solution on the spot. If not, he gets Laurent Nicolas and the third man in their trio involved: Jocelyn Ranc. Ranc is as senior an expert as Nicolas. He is a chemist at Clariant’s application lab in Portes-lès-Valence. »In the lab, we can recreate almost any ground condition in order to test and adapt the composition of a slurry,« Ranc explains. However, he not only keeps in close contact with both Prud’Homme and Nicolas but also personally visits construction sites on a regular basis. »Being that close to what you’re dealing with helps a lot,« he says. »If a contractor runs into any issues, most of the time we can come up with and test a practical solution within a day or two.«

Jean-Michel Dumay can attest to that. He is a site superintendent for Soletanche Bachy, a global industry leader in foundations and soil technology. After 35 years of doing these kinds of jobs all over the world, he considers Grand Paris Express the highlight of his career: »I am sure that everyone who’s worked on this will come out taller and proud of what we’ve accomplished,« he says. »Clariant will have earned its share of this success. Laurent is our advisor in choosing the right products, and Jérémy helps us implement them once they’re delivered. The project would not have advanced the way it has without this close cooperation.«

Tunneling for EOLE

At the forefront of innovation

Clariant delivers bentonite for yet another groundbreaking Paris project in urban mobility.

While Grand Paris Express circles central Paris and extends lines outwards, another megaproject is tunneling its way right into the heart of the French capital. EOLE, or the Est Ouest Liaison Express, is a new commuter train project by SNCF Réseau, the infrastructure division of France’s national railway company. EOLE connects, as the name suggests, communities to the east and west of Paris. It will add three new stations and eight kilometers of underground tracks to connect another 47 kilometers of modernized tracks to the existing line E. Parts of the tunnel, which is due to be finished as early as 2022, run underneath the eighth arrondissement and even just a few hundred meters away from the Arc de Triomphe. Upon completion in 2024, EOLE is expected to carry over 650 000 passengers every day. Clariant is once again involved as the key supplier for bentonite. In this case, however, the material is used as a support fluid for a new type of fully automated slurry shield boring machine. The consortium for the tunnel section (GC-TUN) is made up of Bouygues Travaux Publics, Eiffage Génie Civil, Eiffage Fondations, Razel-Bec, and Sefi-Intrafor. It uses a slurry shield tunneling machine that excavates the tunnel and installs concrete rings to make up the walls. This machine, measuring over eleven meters in diameter, uses a bentonite-based drilling slurry to stabilize the front face of the borehole and to pump the excavated soil to an impressive regeneration unit located on the surface. The soil is transported via a temporary pipeline from the construction site to the banks of the River Seine, from where it is then shipped away. The bentonite slurry is sent the other direction right up to the head of the boring machine. This reduces the number of truck movements by about 75%. Over the course of the entire project, Clariant will have delivered several thousand tons of bentonite to help excavate a total of about 1.3 million tons of soil.

A smaller ecological footprint

Proximity matters in other ways too. The bentonite used in Paris is mined and refined at two French Clariant sites. One is located just two hundred kilometers north of Paris, in the coastal town of Le Tréport. The other lies to the south, in Portes-lès-Valence, midway between Lyon and Avignon. Not having to ship the clay halfway around the world further improves its ecological footprint. That matters with Grand Paris Express. By design, the project will not only make the city’s transportation system a lot more sustainable, it also contractually obliges each and every company involved to minimize their ecological impact. In order to reduce the number of trucks on the city’s streets, for example, some of the required materials and as much excavated soil as possible is moved with barges on the River Seine or even pipelines. »Contractors also commit to reusing as much water, gravel, and sand as possible – preferably on-site,« says Nicolas.

Besides providing a level of technical service that, today, is exceptional in the industry, Clariant also delivers an especially effective product. »There are cheaper options on the market,« says Nicolas. »But using our highly tailored premium bentonite allows reducing the required amount by up to half. Additionally, the increased performance allows for a longer lifetime of the drilling fluids. That again translates to fewer trucks on the road and less space taken up on an already cramped construction site.«

Remarkable material

Bentonite is a naturally occurring clay used in many different industries.

Proximity matters

Clariant mines and refines its bentonite for Grand Paris Express at two sites in France.

A new traffic artery

The longest stretch of the new tunnel for EOLE runs underneath the historic heart of Paris.