Engineering serendipity

Contribution to SDGs

This story is an example of Clariant’s contribution to SDG 12. Read more in Sustainable Development Goals

-

Ensure sustainable consumption and production patterns

Clariant’s Biotechnology Center in Planegg near Munich uses nature’s playbook to find powerful biochemicals and new business opportunities.

The history of scientific discovery is full of happy accidents. From X-rays to penicillin and from rubber tires to Velcro – some of humanity’s most consequential discoveries and inventions were to some degree hard-earned flukes. Purposefully engineering the right conditions for serendipity to strike may then be the best way to drive innovation. This is exactly what Clariant does at its biotechnology research facility – by using a Nobel Prize-winning mix of high tech and natural diversity.

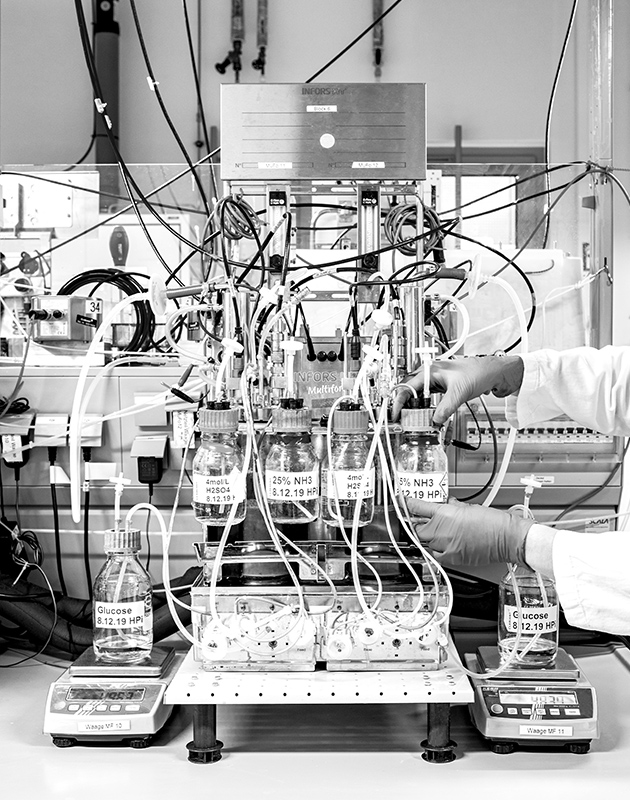

»You’re looking at the first step in scaling up our fermentation,« says Lina Tubes, a scientist in the fermentation and downstream team at the Clariant Biotech Center (CBC) near Munich, as she points to a row of small glass containers filled with a bubbly brownish fluid and entangled in a seemingly chaotic mess of tubes, cables, valves, and displays. The air is filled with the whirr of countless pumps and fans as well as a distinctly yeasty smell. Lina Tubes works on industrializing fermentation and downstream processes. »A process that works in a glass bottle is one thing,« she says as she leads us along another row of ever larger stainless-steel reactors. »Getting the same fermentation to work in an industrial fermenter measuring many cubic meters poses a whole range of challenges every time,« she says. For a start, there are inevitable differences in temperature and pressure throughout such a large vessel that the fickle microorganisms need to cope with.

Precision fermentation – the art of getting microorganisms to produce specific and often complex organic molecules such as proteins – lies at the heart of most biotechnological productions. And it is the core driver in the CBC’s efforts to develop new business in the biotechnology and biofuel sector. The CBC was established in 2015 to bundle and intensify all of Clariant’s endeavors in industrial biotechnology. There are currently over 100 people working at the CBC. It is located in Planegg. The small suburb of Munich is home to an impressive cluster of biotech firms. Both the biotech campus of the Ludwig Maximilian university and the renowned Max Planck Institute of Biochemistry are just a few minutes away. In fact, the Max Planck cafeteria is a lunchtime hotspot for biotech professionals. »Being on the head chef’s menu mailing list is a must for anyone who works around here,« says Michael Zavrel, who heads Development and Biomanufacturing at the CBC.

GERMANY

Going strong

The CBC was established in 2015 to intensify Clariant’s endeavors in industrial biotechnology.

Starting small

Scaling up biotechnological processes for industrial use is an important part of the work at CBC.

Hard at work

These bioreactors at the CBC contain billions of specifically tailored microorganisms that churn out desired compounds.

Zavrel is one of many at the CBC initially hired to work on a novel process for converting agricultural waste into biofuel. »That project was what essentially sparked the whole biotech group for Clariant and established our impressive expertise in second-generation biofuels based on non-food biomass,« says Markus Rarbach, who was an integral member of the research team at the time and today heads up Clariant’s Business Line Biofuels & Derivatives. »It is an exemplary success story that came out of the CBC.« The final process has since been brought to market as sunliquid® technology. Clariant broke ground on its first-of-its-kind full-scale commercial ethanol plant in Romania in 2018, and the company is licensing the technology to others. Nonetheless, Lina Tubes and others at the CBC are still working on future process improvements to increase the efficiency of the technology for feedstocks which are abundant in different parts of the world, including wheat straw in Europe, rice straw in Asia, sugar cane bagasse in South America, and corn stover in the USA.

A key component of the sunliquid® process, as in most industrial biotech, are enzymes. They convert indigestible parts of wheat, rice, and other biomass into a form of sugar that microorganisms can only then convert into biofuel. Such enzymes, or »biological catalysts,« are highly complex protein molecules that can induce and speed up chemical reactions. They serve a wide range of functions in any living organism. But they can also do nifty tricks for a host of industries by promoting reactions that are otherwise very difficult to achieve.

Asking an expert

»At the very heart of sustainable chemistry«

Ling Hua

Head of Group Biotechnology, on the impact of »directed evolution« and the overall benefits of industrial biotech

Ling, you’ve worked with Nobel Prize laureate Frances Arnold, haven’t you?

Yes, about 20 years ago. In fact, she was influential in getting me my first job. I was looking for a post-doc position in her lab and she forwarded my CV to a friend of hers, who was building a biotech start-up. I was one of their first hires and later collaborated with Frances and her lab to work on enzymes for the bioconversion of active pharmaceutical ingredients.

How has »directed evolution« impacted your own work?

It is a powerful tool for any of us playing in the field of industrial biotechnology. Without directed evolution, we only can look for whatever enzymes or microorganisms are out there in nature, most of which obviously have not evolved to fit industrial applications. Frances’ contribution in directed evolution changed that and now allows us to evolve enzymes specifically to fit any industrial application and to enable chemical conversions through biocatalysis that were impossible before.

How can this concept and industrial biotechnology in general benefit mankind?

By creating diversity in the lab and then selecting for desired properties via High-Throughput Screening we are using nature’s algorithm to find powerful enzymes quickly and reliably. Those can open up opportunities for industrial enzymes in various applications. Anything from efficient detergents that help washing machines and dishwashers save energy and water to the use of biocatalysis for more sustainable transformation pathways in chemical and pharmaceutical productions.

Speaking of the environment, what can the Clariant Biotech Center (CBC) contribute to a sustainable future?

Research at CBC has brought us the sunliquid® technology to breakdown biomass into sugars and then ferment them into ethanol with a high yield. This alone contributes tremendously to the circular economy and reduces CO2 footprints. In addition, microorganisms allow us to produce even the most complex compounds very energy-efficiently and using natural renewable resources. At the CBC, we also focus on the development of biobased and fully biodegradable materials. So I see our work at the very heart of Clariant’s efforts towards sustainable chemistry. And keep in mind, industrial biotech as a discipline is still fairly young. So is the CBC. We’re only getting started!

For millennia, enzymes have played a role in making bread, cheese, and beer. More recently, they have found applications in anything from personal care and pharmaceuticals to industrial processes and household products. Enzymes help modern laundry detergents dissolve stains at lower temperatures. Others can stop what’s called »pilling.« »We program these enzymes to essentially nibble away those tiny ugly knots that form on synthetic and woolen fabrics,« says Timothy O’Connell, who heads Research and Application at Clariant Biotechnology. O’Connell joined Clariant in 2016 from one of the world’s largest household care companies. »I’ve spent much of my professional life battling food stains,« is how he puts it. While the right enzymes can make life a lot easier, »programming« them is extremely difficult.

Copying nature’s design process

That’s where a method called »directed evolution« comes in. It was pioneered in the early 1990s by an American chemical engineer named Frances H. Arnold at the California Institute of Technology (Caltech). In 2018, it won her the Nobel Prize in Chemistry. Arnold herself has called it a way of »copying nature’s design process.« The idea is to take any microorganism, such as a bacterium or fungus, that has the potential to produce a certain type of enzyme. The next step is to then spawn thousands upon thousands of new varieties of that organism by inducing random mutations. This can today be done easily and reliably with certain chemicals, radiation, or even just with UV light. After that, it’s a matter of selecting which, if any, of those new organisms produce an enzyme that fits the task at hand.

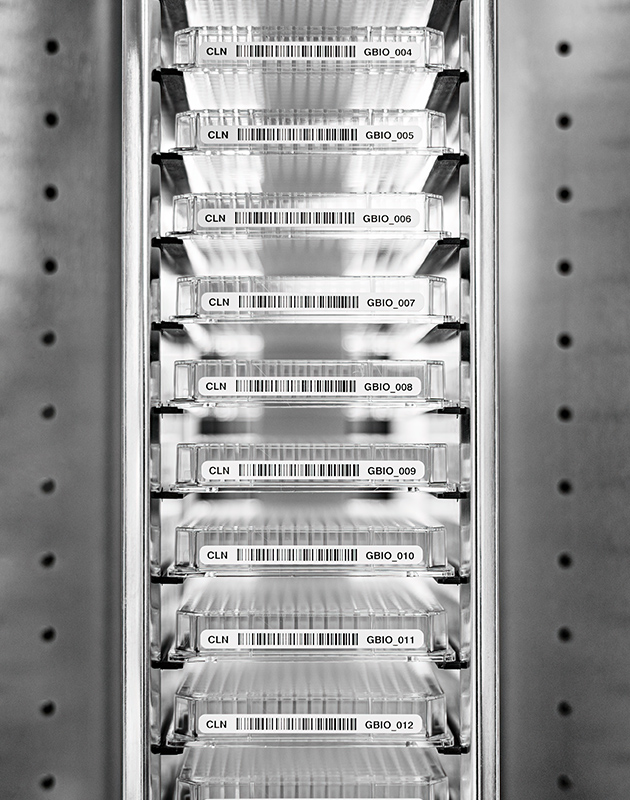

Clariant uses proprietary technology to carry out protein engineering and directed evolution. That involves first creating diversity both at the protein and the organism level and then selecting for the specific properties that fit the desired industrial application. However, testing thousands upon thousands of individual organisms and proteins is both hard and tedious. Luckily, Katja Kirsch has two untiring robotic arms at her disposal, bulky metal contraptions that rotate and jerk at all kinds of unnatural angles. Kirsch is a scientist at the CBC and her robotic arms are part of a High-Throughput Screening (HTS) system. Clariant runs two of these at the CBC. The robots slide up and down a lab bench taking every variant sample through various tests to determine which one fits the intended process best. It is Kirsch’s job to design the specific sequences of steps and tests. To speed things up, each sample occupies a position in a microplate, a plastic rectangle with up to 1 536 wells or tiny test tubes, arranged like boxes in a crossword puzzle. »For size reference: An individual well holds only a fraction of a raindrop,« says Kirsch.

»We run thousands of samples per week to select them for specific properties.«

Katja Kirsch Scientist, Group Biotechnology

Once the robots have taken the microplates through the tests, they store them in a fridge. »With this setup, we are able to process many thousands of samples per week,« says Kirsch, as she points to a display next to the fridge. It shows results for each and every well on any of the microplates in the fridge. Those results can be the concentration of a specific enzyme or any of its useful properties needed in an industrial process. They can even be the result of thousands of tiny washing cycles. For that, Kirsch will have put a minuscule piece of purposely stained cloth into each of the wells before she lets a scanner determine how effective each enzyme was in removing the stain. »Then it’s just a matter of defining which variants give the results that we find promising, and the robots will select the corresponding samples from all the plates in the fridge for further tests or as starting point for a new cycle of evolution,« explains Kirsch. That’s the beauty of directed evolution: The CBC uses nature’s toolbox to come up with new solutions to a problem and then has robots select the best fit for an industrial process, which is then developed for production.

One of the latest innovations using directed evolution to come out of Clariant’s Biotechnology is a brand new biopolymer. »The term gets thrown around a lot,« says Zavrel. »For us, a biopolymer is both derived from a natural, renewable resource and is also fully biodegradable.« He and his team were able to develop such a material with the help of a microorganism. »It produces the polymer as a defense mechanism using natural sugars,« says Zavrel. What’s even more interesting, the biopolymer does not pollute the ocean with microplastics because natural microorganisms can completely break down and digest any leaked product just like a regular sugar. »This could be a great sustainable alternative for traditional polymers in many different industries,« Zavrel says.

A new solution to an old problem

Another recent innovation connects the CBC with one of mankind’s oldest uses for fermentation: brewing beer. While working on sunliquid® in its earliest stages, Zavrel developed an entirely new process to extract the alcohol from a fermentation. He stumbled upon the solution by accident when he stored a sample of the brew together with one of Clariant’s own products. What he found was that the material soaked up alcohol like a sponge. In a small room next to the main laboratory, Zavrel assembled an apparatus, which is about the size of a small car, and tried it with a case of lager beer that he bought from the shop across the street. Without much tinkering, he was able to reduce the alcohol level by 90%. That left him with a beer that qualifies as »alcohol-free« but still has all its complex flavor compounds intact. »This technology fits perfectly the unmet needs in the non-alcoholic beer or wine market,« says Zavrel. He is not alone in seeing the potential. According to market research performed by external partners as well as internal market intelligence, sales of non-alcoholic and low-alcohol drinks are growing steadily in most industrial countries, in line with other health-conscious trends. Even in beer-thirsty Germany, non-alcoholic brews are the only kind that have seen substantial growth in recent years. And then there are new markets in the Middle East and parts of Asia, where people abstain from alcohol for religious reasons.

Hold the booze

How Clariant’s new way of dealcoholization works

Clariant’s unique process for dealcoholization uses a method called gas stripping. A pump streams the mixture of carbon dioxide, water vapor, alcohol, and esters accumulating atop the brew through a bed of zeolite. This specific type of microporous aluminosilicate is produced by Clariant’s Business Unit Catalysts. Its microscopic pores capture only the alcohol. That is because water molecules are too small and the complex esters responsible for distinct beer aroma are too large to get stuck. Both can simply be pumped back into the beer. Once the zeolite is saturated with pure alcohol, it’s then easily emptied out with a vacuum pump, and the cycle continues.

As with any of its innovations, Clariant’s Biotechnology team has intensively evaluated the market potential early on. But unlike most new technologies coming out of the CBC, dealcoholizing beer is a completely new business for Clariant. »That’s why we’ve put resources for commercialization in place ourselves and want to act as an incubator in this development phase,« says Andreas Reindl, who heads Business Development at Clariant Biotechnology. »The key is to now bring this true innovation to market quickly, ideally starting with strong mid-sized brewing companies.« This means that Clariant Biotechnology is breaking new ground for the company. Then again, being open to new opportunities seems essential to Clariant’s Biotechnology. Or as Louis Pasteur, one of the fathers of microbiology, once famously said: »Chance favors only the prepared mind.«

Harnessing diversity

With the help of state-of-the-art automation, the CBC screens microorganisms by the thousands.

Michael Zavrel

Head of Development & Biomanufacturing, Group Biotechnology

A substance that lowers the activation energy, thereby increasing the rate of a chemical reaction without being consumed by the reaction itself. View entire glossary