Moving Towards the Global Hydrogen Economy

A world running on hydrogen.

An old dream coming true.

Across the globe, countries are working to shift their energy systems and industries from fossil fuels to renewable energy. Hydrogen will play a decisive role in these efforts.

A clean hydrogen economy offers a unique way of tying together different forms of energy generation and consumption – for example, renewable power to generate hydrogen for use in steel production, fuel cell applications, or chemical production. Meet some of the people and products at Clariant that are helping to make this vision a reality.

Why Hydrogen?

-

Abundant

Hydrogen is by far the most abundant atom in the universe. On earth, hydrogen is found mostly bound in water and organic compounds. It is an essential part of all organic life on earth.

-

Versatile

Hydrogen can be used to fuel cars, trains, ships, and even planes. It can be turned into electricity and heat both on an industrial and a domestic scale. Plus, hydrogen is an essential feedstock for a host of chemical productions, such as ammonia or methanol.

-

Clean

The only emission from burning hydrogen is water vapor. The process can be reversed by using electricity to split water into hydrogen and oxygen. Using renewable electricity for this process makes the resulting hydrogen carbon-neutral.

-

Reliable

Electrolysis can produce hydrogen wherever electricity and water are available, which makes for a decentralized supply system. Because of its many uses and the fact that it can be converted back into electricity, hydrogen can also work as a buffer for the power grid.

This story is an example of Clariant’s contribution to SDGs 7, 9, 13 and 17.

Read more in Sustainable Development Goals

What is electrolysis?

Electrolysis is the most promising option to produce hydrogen from renewable energy. It uses electricity to split water into hydrogen and oxygen. The necessary electrolyzers can range in size from small appliance-sized equipment for decentralized hydrogen production to facilities the size of today’s power plants. If run on renewable power, these electrolyzers produce what’s commonly referred to as »green hydrogen.«

Electrolysis at a glance

An electrolyzer consists of an anode and a cathode separated by an electrolyte. While there are several types of electrolyzers, which differ mainly in their type of electrolyte, the underlying principle is always the same: Applying a voltage between the anode and the cathode causes water molecules to split into hydrogen and oxygen. So-called alkaline electrolyzers are most common today and have been available for decades. But there are newer approaches that promise higher efficiency. Some of them, however, are still in the early stages of development.

Green, gray, and blue – The colors of hydrogen

Hydrogen is a colorless gas. However, three color terms are commonly used to designate different types of hydrogen production and their potential climate impact.

-

Green

Green hydrogen is produced in electrolyzers running on renewable electricity. It is mostly climate-neutral.

-

Gray

Gray hydrogen comes from steam-methane reformers. Its production emits large amounts of carbon dioxide.

-

Blue

Blue hydrogen is essentially gray hydrogen whose carbon emissions have been captured and stored underground.

The Vision

What would a hydrogen economy look like?

-

generation +

production -

transport +

storage -

energy +

material use

Wind/Solar

Hydrogen can be generated from water by using electricity. Employing solar, wind, or hydroelectric power yields »green hydrogen,« which is carbon-neutral.

LOHC – Tank Truck

Chemically bound in a so-called liquid organic hydrogen carrier (LOHC), hydrogen can be safely transported and stored using conventional fuel infrastructure. Learn how Clariant helps pave the way

Pipelines

The easiest and most efficient way to transport hydrogen is by pipeline. Parts of today’s natural gas grid could transport hydrogen from producers to consumers.

Steam methane reforming

By far the most common way of producing hydrogen today is steam-methane reforming. It extracts hydrogen from natural gas but produces ten or more tons of carbon dioxide per ton of hydrogen. Learn how Clariant is helping to improve this

Decarbonizing

Many industries have the potential to decarbonize their processes by using hydrogen directly. Steel production is one example where companies are already evaluating the switch to hydrogen. However, this requires large investments and vast amounts of carbon-neutral hydrogen.

Another approach to decarbonization uses hydrogen to turn captured carbon emissions into useful feedstocks for other chemical productions. Learn how Clariant is involved in the Carbon2Chem project

Ammonia

Combined with atmospheric nitrogen, hydrogen is turned into ammonia, which is a crucial fertilizer in agriculture, an important chemical feedstock, and a potential fuel for marine transport and decarbonized energy production. Learn more about Clariant’s ammonia catalysts

Heating

Hydrogen can be used as a climate-neutral heat source both in industrial and domestic applications. Adding it to the natural gas supply can reduce the overall climate impact of natural gas without requiring much adjustment to current installations.

Electricity

Using »green hydrogen,« fuel cells, or gas turbines, hydrogen can produce electricity without any carbon emissions. This makes hydrogen a useful option for storing renewable energy. There are industrial and domestic solutions available that use hydrogen to generate heat and electricity simultaneously.

Clariant’s catalysts are key in transforming carbon monoxide and carbon dioxide into various valuable chemicals.

Methanol

With the help of special catalysts, hydrogen and carbon are converted into methanol. This type of alcohol is a widely used feedstock for the chemical industry and a potential drop-in fuel for vehicles. Learn how Clariant helps drive innovation in this field

Methane

Using catalysts, hydrogen can turn carbon dioxide collected from industrial exhausts into methane, the main component of natural gas. Learn how Clariant has helped to pioneer this technology

X

Hydrogen and captured carbon could together be the basis for an ever-greater greater range of valuable chemical products. By soaking up carbon emissions, these products will help fight climate change. Learn how Clariant works to make it a reality

Swipe and click an area to find out more about the process

Click an area to find out more about the process

Combined efforts – How hydrogen helps multiple industries fighting climate change

Hydrogen is extremely versatile. From steel to glass, from electronics to specialty chemicals – hydrogen is used in many different industries both as a reactant in certain processes and as an essential building block for products themselves. Plus, there is the possibility of using hydrogen as a carbon-neutral source of heat and electricity. These many different applications offer the chance to link vastly different sectors of the economy.

Using electrolysis to produce hydrogen effectively stores renewable energy in a physical form that can be transported and is useful to many different industries. This makes smarter use of the decentralized and fluctuating power from solar and wind energy. It helps to smooth peaks in supply and demand, which in turn could help boost investments in renewable energy. Using parts of the existing gas infrastructure makes transporting renewable energy as hydrogen easier than having to remodel the current power grid.

Green hydrogen can help industries decarbonize, either by replacing fossil fuels directly or by creating synthetic fuels that are carbon-neutral. Wherever carbon emissions are unavoidable, hydrogen opens up ways to capture and use these emissions as raw materials.

From greenhouse gases to valuable raw materials

Carbon2Chem is an ongoing cross-industry project funded in part by Germany’s Federal Ministry of Education and Research. The project works on processes to capture gas emissions, predominantly from steel mills, and to turn them into valuable raw materials for the chemical industry. Clariant is one of 17 industrial and academic partners involved.

More about Carbon2ChemFilling the Gaps

How Clariant is helping to solve current challenges for the hydrogen economy

Why it matters

While a global hydrogen economy offers the chance to decarbonize many aspects of modern life, there are still some challenges. For one, generating carbon-neutral or »green« hydrogen from electrolysis requires a lot of renewable electricity. More efficient methods of electrolysis are on the horizon. However, there is still nowhere near enough green hydrogen available to satisfy current demand – let alone the demand of ever more industries turning to hydrogen in the near future. That is why improving today’s methods of hydrogen production can help ramp up production and still reduce greenhouse emissions and energy consumption.

Hydrogen is relatively easy to transport via pipelines, and there is even the possibility of using parts of the current gas grid to do so. That is great news if hydrogen is to help make energy systems more diversified and decentralized. However, linking remote producers to the grid may turn out expensive and time-consuming. The same is true for establishing a tight network of hydrogen fueling stations for cars and trucks. That is why it is important to find safe and efficient new ways to transport hydrogen.

Many industrial applications rely on hydrogen, and even more could do so in the future. However, switching from hydrocarbons to hydrogen is not an economically or chemically viable option for every process. Using hydrogen to make conventional fuels and feedstocks themselves carbon-neutral could thus pave the way to a hydrogen economy that works for everyone.

Andreas Geisbauer

Senior Technology Scout & Innovation Manager, Business Unit Catalysts

»From producing to transporting and subsequently using hydrogen, catalysts are bound to play a key role in almost every part of the hydrogen economy,« says Andreas Geisbauer. As Senior Technology Scout & Innovation Manager for Clariant’s Catalysts Business Unit, Geisbauer is far from impartial, but he has also examined more new technologies than most. One very promising innovation involves improving the way most of the world currently generates hydrogen.

Today, more than 90 percent of all hydrogen produced worldwide comes from steam-methane reforming. The process uses steam and catalysts to break up methane, the main component of natural gas, into hydrogen and CO2. Per ton of hydrogen, the process commonly produces ten or more tons of CO2. That is why today, according to the International Energy Agency, hydrogen production worldwide is responsible for around 830 million tons of CO2 emissions per year, equivalent to those of the United Kingdom and Indonesia combined. »EARTH® technology offers a way to change this,« says Andreas Geisbauer.

The Enhanced Annular Reforming Tube for Hydrogen, or EARTH®, technology was developed by Technip Energies, a global leader in the energy industry, with the help of Clariant’s Catalysts Business Unit. EARTH® can increase reforming capacity by up to 20 percent while reducing specific fuel consumption by up to 30 percent and the hydrogen CO2 footprint by up to ten percent.

»Most importantly, this combination of a new technology and a new catalyst can be dropped into almost any current steam reforming plant without major modification,« says Geisbauer. EARTH® technology involves a geometric arrangement of tubes and catalytic surfaces that are installed inside the regular reformer tubes. They greatly increase both the surface and the activity of the catalyst while making better use of the energy. »This means that, while other methods of hydrogen production are still slow to ramp up, we can very effectively improve today’s hydrogen economy to deal with rising demands, while at the same time reducing its climate impact.«

A new way to safely transport and store hydrogen

Hydrogen itself is neither toxic nor otherwise harmful to our environment. But it is very volatile and not particularly easy to transport because of its very low density. The most efficient ways are pipelines or parts of the existing natural gas grid. However, building a nationwide hydrogen infrastructure is still costly and time-consuming. Some potential hydrogen suppliers and consumers may never be able to connect to the grid cost-efficiently.

One attractive solution to this problem are so-called liquid organic hydrogen carriers, or LOHCs. These oil-like liquids can soak up hydrogen atoms in their molecular structure. Using catalysts from Clariant, such LOHCs can be chemically loaded with hydrogen. The resulting oil is very safe to handle and transport with conventional fuel trucks. Another of Clariant’s catalysts helps to »unload« the LOHCs again on-site, leaving the consumer with pure hydrogen and an LOHC ready for »re-loading.«

Hydrogenious Technologies is an award-winning German start-up that works to perfect loading and unloading such LOHCs. In 2018, Clariant partnered with Hydrogenious to tailor the catalyst to the process and make the system more efficient and scalable. Together, Hydrogenious and Clariant work on LOHC-based systems compact enough to run onboard trains, ships, and even commercial vehicles.

Thomas Cotter

Business Development Manager for Power-to-X, Business Unit Catalysts

»These are completely new value chains, and some of our products are at the very heart of them,« says Thomas Cotter. As a Business Development Manager for Clariant’s Catalysts Business Unit, Cotter works to advance a whole range of joint Power-to-X projects at Clariant – some with industry giants, some with trailblazing start-ups. Most of the technologies involved are still in development. But they play to Clariant’s strength as a catalyst specialist, and their implications are impressive. »Essentially, hydrogen allows us to take renewable electricity and industrial carbon emissions and turn them into more climate-friendly fuels and chemical feedstocks,« Cotter explains. »And it’s the right catalyst that makes it all work.«

That is why Clariant is involved in projects like Carbon2Chem, the initiative around ThyssenKrupp, a German steelmaker that hopes to turn smelt gases into methanol – with Clariant catalysts. »As early as 2013, we provided catalysts and the necessary know-how for Audi’s Etogas project to turn carbon dioxide into methane, a substitute for natural gas.« For Ineratec, a spin-off from the Karlsruhe Institute of Technology (KIT), Clariant provides catalysts that power a groundbreaking gas-to-liquid technology. It allows Ineratec’s modular plants to turn carbon dioxide from the atmosphere into carbon-neutral ready-to-use diesel or gasoline.

Developing such a comprehensive conversion from start to finish requires a lot of Clariant’s know-how. »Ineratec’s process, for example, involves several different steps. Each relies on a different Clariant catalyst – from our HyProGen® R70 to the MegaMax® range to METH™ 134,« Cotter explains. »Plus, we contribute catalysts and know-how in purifying both the hydrogen and carbon streams going into such a process.«

Cotter sees not only promising business opportunities in these Power-to-X innovations. »They may also turn out to be our best bet for turning around climate change because they help entire industries decarbonize by providing them with carbon-neutral fuels and feedstocks.«

»Essentially, hydrogen allows us to take renewable electricity and industrial carbon emissions and turn them into more climate-friendly fuels and chemical feedstocks.«

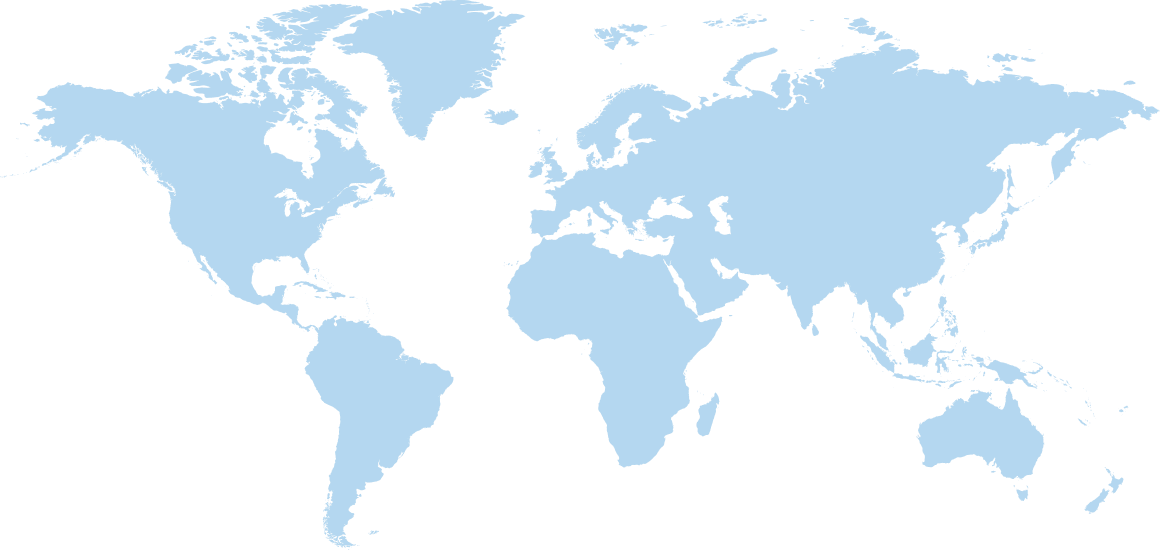

Who is pushing for hydrogen?

An overview of national hydrogen strategies across the world

United States of America

As with most other climate and environmental standards, California leads the way among US states in its efforts to promote hydrogen. By 2030, California hopes to install at least one thousand hydrogen fueling stations for a projected fleet of one million fuel cell cars.

Chile

Chile is the first country in Latin America to publish a national hydrogen strategy. The country’s low-cost renewable energy from high and constant wind speeds puts it at an advantage. Chile aims to produce the cheapest green hydrogen worldwide by 2030 and become a top-three exporter by 2040.

Norway

The country that owes much of its prosperity to its gas exports plans to drastically reduce its carbon footprint by 2050. Using depleted gas fields as underground storage for captured CO2 could become part of Norway’s new business model and a vital part of Europe’s hydrogen economy.

The Netherlands

Using offshore wind energy and existing gas grids, the Dutch hope to sell hydrogen to their neighbors. Once Europe’s largest gas exporter, the Netherlands is phasing out natural gas production and hopes to become the continent’s new »hydrogen valley.«

Germany

The country’s national hydrogen strategy aims to make Germany the world’s leading provider of modern hydrogen technologies. The government earmarked seven billion Euros for promoting hydrogen technologies in Germany plus another two billion for international hydrogen partnerships.

European Union

Green hydrogen takes center stage in the European Green Deal presented in 2019. The EU aims to install at least six gigawatts worth of electrolyzing capacity by 2024 and 40 gigawatts by 2030. By then, the production of renewable hydrogen is expected to reach ten million tons per year.

Morocco

Europe’s neighbor to the south could supply the continent with vast amounts of solar energy at a fraction of the cost of generating it in less sunny regions. Such plans have been on the table for decades. Turning Moroccan solar and wind power into hydrogen and pumping it to Europe via pipelines or shipping it as methanol produced from the conversion of hydrogen with carbon dioxide could finally make them a reality.

Saudi Arabia

The world’s largest oil exporter is looking for new business models. Its vast oil and gas reserves make producing hydrogen relatively cheap. Capturing and storing CO2 underground in depleted oil and gas fields is also cheaper than elsewhere.

South Korea

When it comes to promoting hydrogen-powered cars, South Korea is among the most ambitious countries on the planet. Its government wants South Korea to become the leading manufacturer of fuel cell cars by 2030 and have all commercial vehicles in the country run on hydrogen by 2035.

Japan

Japan, which already imports most of its energy, has been at the forefront of using hydrogen in fuel cell cars. The national government aims to reduce the price for hydrogen by 90 percent by 2050, for example, by importing vast amounts of hydrogen from Australia.

Australia

By using its large coal reserves to produce hydrogen and storing the resulting CO2 underground, as well as by exploiting its huge renewable potential from wind and sun to split water to hydrogen and oxygen, Australia hopes to become a global exporter for a much more future-proof energy carrier.

Swipe to move map

2020

Clariant joined the Hydrogen Council in 2020. The Hydrogen Council is a global initiative of almost 100 leading energy, transport, and industry companies committed to a long-term energy transition using hydrogen. It was founded at the 2017 World Economic Forum in Davos.

Clariant + Hydrogen CouncilMartin Vollmer

Chief Technology Officer

-

This is not the first time that hydrogen has been hailed as the energy of the future. What’s different now?

We’ve come a long way technology-wise and, more importantly, in terms of policy. Across the globe, governments now prioritize hydrogen as a key technology to reach net carbon neutrality. Many have earmarked billions for hydrogen technology and infrastructure as part of their post-COVID recovery plans. The EU’s hydrogen roadmap alone hopes to create a million hydrogen-related jobs by 2030 and 5.4 million by 2050.

-

What do you see as the biggest hurdle?

Prices for green hydrogen need to come down – by a lot. They are linked directly to the cost of renewable electricity and increased production capacity. Luckily, we’re on the right path. The International Energy Agency predicts a price drop of 30 percent for green hydrogen by 2030. Still, ramping up green hydrogen production will take some time. In the meantime, I believe we should boost hydrogen usage and improve our current infrastructure to get the ball rolling.

-

What is Clariant’s role in the hydrogen future?

As a solution provider to many different industries, we believe that hydrogen is key to achieve the greenhouse gas reduction targets and Clariant contributes to accelerate the deployment of these technologies. Many of our catalysts, for example, are already used in innovative hydrogen applications. This is no coincidence. Clariant has been driving R&D and cross-industry collaborations in this field for years – because building the hydrogen economy fits our sustainability goals and also makes perfect business sense. The Hydrogen Council, which Clariant joined in 2020, anticipates hydrogen and hydrogen technologies eventually becoming a global market worth $2.5 trillion.