The health and safety of any person is and continues to be extremely important to Clariant. For Clariant’s consumers and customers, safety is addressed by Clariant’s product stewardship initiatives (see chapter Product Stewardship). However, to ensure the safety of Clariant’s hard-working and diverse employees, many strategic and multifaceted health and safety programs are set in place. In other words, occupational health and safety is a holistic commitment that incorporates much more than just wearing necessary chemical safety gear.

Safety starts with a resolved, safety-oriented leadership culture

Employee safety and accident prevention means that using safety gloves and goggles are second nature. It also requires that a set of cohesive management programs and leadership measures back Clariant’s occupational health and safety strategy. AvoidingAccidents@Clariant, a global program aimed at creating safe working environments and raising awareness of safety concerns is an example of this. When AvoidingAccidents@Clariant first started in 2007, Clariant had a lost time accident rate (LTAR) of 0.92. The LTAR, which reflects the number of occupational accidents with at least one day of work lost in relation to 200 000 hours of work, has reduced by more than half since 2007, and in 2016, Clariant had an LTAR of 0.19.

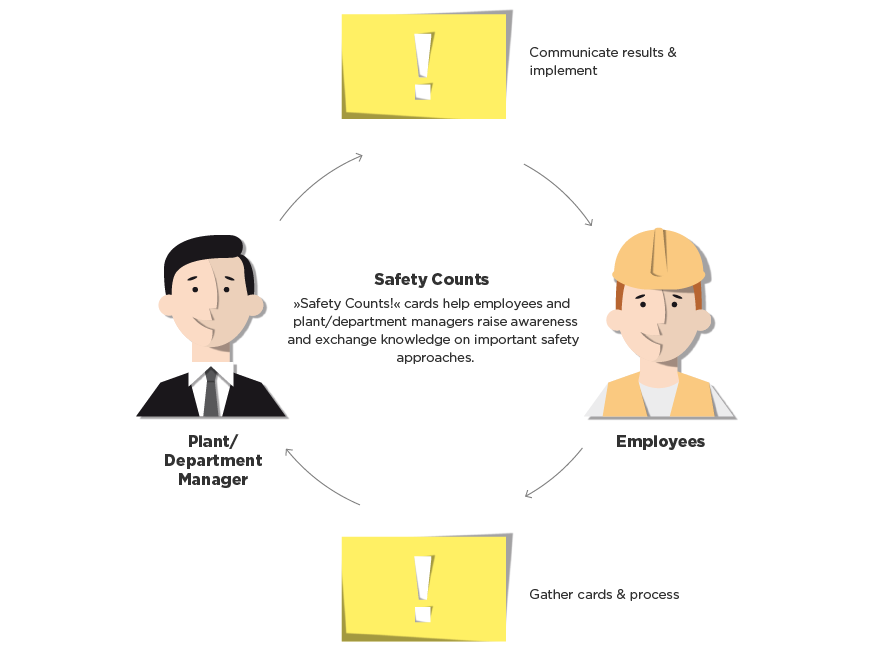

Clariant’s »Safety Counts!« cards also play a part in ensuring health and safety, often eliminating critical situations that could lead to an accident. Every month, safety deviations that occur at the sites are recorded with these cards, and implemented improvement measures are shared locally. This allows the production teams to share the lessons they have learned from accidents and safety deviations, correcting behavior and operations (where necessary), and promoting a preventive mind-set throughout the entire company.

0.19

was the lost time accident rate (LTAR) per 200 000 hours of work in 2016 (2015: 0.17)

Prevention means taking action before anything happens

For Clariant, the most critical health and safety goal is zero accidents. The most effective way to reach this goal is to prevent occupational and safety accidents from happening in the first place – thus, prevention is at the core of Clariant’s health and safety strategy. Clariant closely monitors everything that could lead to an accident, examines its employees’ health on a regular basis, and keeps precise track of accidents – not only of its production teams, but of all staff at all locations.

»The AvoidingAccidents@Clariant program and safety awards are key elements in our striving for our ultimate goal: zero accidents.«

Volker Hautzel Head of Occupational Health & Safety

Safe behavior

Clear safety rules and mandatory personal protective equipment like safety shoes and safety glasses help to prevent injuries, but additional regular safety and health trainings combined with lessons from internal trainers that encourage safe operations embed safety into the culture and habits of Clariant’s employees. Clariant Safe Behavior Trainings (CSBT), for example, are conducted by internal trainers at Clariant locations to spread and ingrain health and safety behaviors.

Awards and recognition

Winning safety: our safety awards

In 2015, Clariant’s Daya Bay, China, production site received Clariant’s inaugural Platinum Safety Award for demonstrating superior safety performance. With this award, as well as Clariant’s other safety awards, the company motivates employees to continuously strive for safety excellence across all sites.

Safety recognition awards, such as Clariant’s Platinum Safety Award, also incentivize employees at production sites to maintain and improve the highest level of health and safety at their sites. These awards recognize excellent performance in safety, and an entire site will receive an award to foster a team spirit. The Platinum Safety Award, for example, is based on 16 criteria that focus on leadership, training programs, and safety reports. Clariant recently celebrated the inaugural winner of the Platinum Safety Award, Clariant’s Daya Bay site in China. This exciting accomplishment in Daya Bay helps motivate employees to continue improving health and safety practices across the entire company. In addition, the Phoenix Safety Award is presented to one site annually in recognition of the most significant improvement in safety program delivery and performance. In 2016, the Sant Andreu (Spain) site received this award for the first time.

Health and safety: an ongoing commitment

Clariant’s ongoing dedication to occupational health and safety is about both adhering to important safety guidelines – like wearing appropriate protective equipment for certain work – and continuing an open conversation around this important topic to ensure safe behavior. To Clariant, the health and safety of its employees is crucial to its operations and sustainable success.

AvoidingAccidents@Clariant

Safety counts!

Prevention is essential for Clariant

Elements accounting for a successful safety culture

Preventing occupational accidents is an essential component of Clariant’s production activities, and the company’s measures for this purpose greatly exceed legal requirements. Clariant closely monitors everything that could lead to an accident, examines its employees’ health on a regular basis, and keeps precise track of accidents – not only of its own teams, but also those of supervised staff. Clariant’s commitment to the safety of its employees includes clear safety rules and mandatory personal protective equipment to prevent injuries, while additional regular safety and health trainings and a concept of local internal trainers work to implement the concept of work safety in the employees’ awareness. What has been essential for success has been the commitment on the uppermost levels of management, which has led to a distinctive culture and approach with regard to safety. The high quality of the safety programs is proven, for example, by the global OHSAS 18001 certification, an internationally applied standard for occupational health and safety management systems.